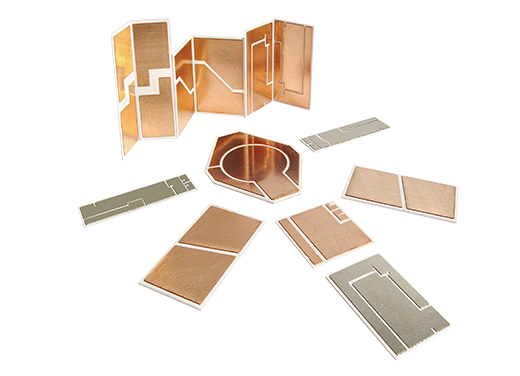

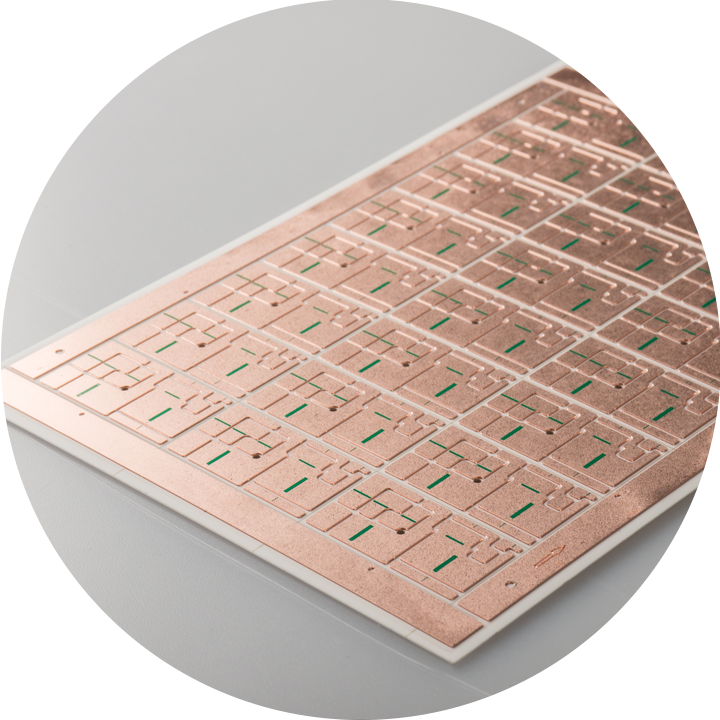

| DCB Ceramic Substrate |

Thermoelectric refrigerator; Wind power stations; Solar energy converter; |

LED lighting; |

|

IGBT module; IPM module; MOS modules; Power supply; |

ABS; Electronic transmission; LED lamp; Hybrid cars; Electric cars; High-speed railway/bullet train; |

White household appliance; Thermoelectric module; |

|